Services

Solar PV Certification and More!

Testing & Certification

SolarPTL provides several product testing and certification services according to various test standards including: IEC 61215, IEC 61730, UL 61703, UL 61730, ANSI/UL 790, IEC 62108, IEC 62670-3, ASTM E1036, IEC 61853 series, ASTM E2527, etc.

The primary target group for this service includes module and component manufacturers.

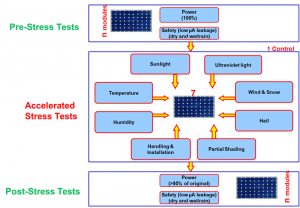

The qualification testing is a short-duration (typically, 60-90 days) accelerated testing and it may be considered as a minimum requirement to undertake reliability testing or market introduction. The primary goal in the qualification testing is to identify the initial short-term reliability issues in the field.

Qualification Testing Concept

The ANSI/UL 2703, ANSI/UL 3703,and IEC 62817 qualification services at SolarPTL provides assurances sought by regulators, EPCs and installers for structural integrity, safety and robustness of PV mounting systems as well as PV/CPV trackers.

Based on existing standards and codes, as well as emerging standards and industry accepted protocols, test programs are available to provide third party proof of conformance to known structural safety requirements and guidelines for North American and International installations. Our goal is to provide clients with the most comprehensive and accurately measured structural/performance characteristics for mounting and tracking systems, delivering greater confidence in system reliability and robustness to all project stakeholders.

Power Plant Testing & Inspection

Results from certification testing (such as IEC & UL) and subsequent factory inspections provide a minimum confidence in product quality; but it falls to the manufacturers to maintain continuous quality assurance of processes, materials, and personnel. Due to global competition and the rush for market entry, this aspect is often neglected; undermining the quality of field-installed PV modules.

Financial institutions and investors want assurance that their investments will yield a ROI through the long-term cash flow generated by power plant. A solar system warranty covers the integrity of the solar modules and protects against extrinsic defects and typically guarantees a certain production percentage over a defined period of operation.

SolarPTL provides independent solar plant quality services using calibrated test equipment for performance degradation analysis and warranty/insurance claims related to string and module performance losses, material/design defects/issues in the field, and weather data accuracy verification. For large solar plants, SolarPTL implements a statistical approach to analyze the performance and defect data obtained using a limited number of fielded modules at a client-specified confidence level and interval. The solar plant services include: visual inspection, performance and commissioning tests according to IEC 62446 series, monitoring, capacity testing and energy testing according to ASTM E2848/E2939, IEC 61724 series, system performance verification according to various models including PVsyst, electroluminescence (EL) imaging for crack detection, infrared imaging (IR) for hot-spot detection, FTIR analysis in the field for fire-related backsheet damage etc, solar racks and trackers. The primary target group for this service includes system owners, investors, developers and insurance companies.

Bankability / Reliability Testing

Reliability is a critical element of continued growth of the photovoltaic (PV) industry. Solar electricity can be cost competitive in many electricity markets today if the solar panels can last at least the length of their warranty, typically 25 years. Design qualification test protocols, such as IEC 61215 and IEC 61730, have been key to mitigating infant mortality, and continued maintenance of these standards can be expected to further improve the overall durability and reliability of products going into the field. However, the adoption process of new standards can take multiple years and it is desirable for the community to be able to use the updated test methods even before they are adopted as standards.

Bankability / Reliability Concept

Other Reliability Services include:

Potential Induced Degradation (PID): IEC 62804

Critical Significance to Sellers and Buyers

- System voltage can cause degradation of large systems by tens of percent in a single year

- Positive or negative grounded system may experience PID depending on the module/cell type

- In floating systems, the modules are subjected to both positive and negative bias stresses

- PID problem can be solved for conventional modules by adjusting the silicon nitride layer on the cells, by using a high-resistance encapsulant, by adjusting the system voltage level and/or polarity, or by using MLPE (module level power electronics)

- PID susceptibility issue can be easily and quickly detected through a few hours or days of inexpensive tests

Photovoltaic module performance characterization:

- Sampling requirements per UL 4730

- Module calibration per ASTM E1036 or IEC 60904-1 or EN 50380

- Complete temperature-irradiance matrix per IEC 61853

- Spectral response

- Angle of incidence (AOI) effects

- CPV performance characterization

- Performance modeling (included PVsyst) module parameter files

Long Term outdoor Exposure (LTOE) Services

SolarPTL outdoor solar test facility features robust data acquisition sensor and testing equipment with methods developed through years of experience in academic research and qualification testing.

SolarPTL provides beta site testing offering additional quality assurance for suppliers, purchasers, designers and installers. Beta sites identify potential system failure modes and serve as a validation step in the procurement process.

SolarPTL in Tempe, AZ has over 100,000 sq ft. (nearly 10,000 sq. meter) of available working space with 480VAC utility interconnection and process water on site. Client installation options includes raw land, or utilize existing fixed-tilt racks, 2-axis solar trackers, or a large pitched rooftop built to California specifications.

Located in one of the sunniest spots on Earth with an average daily irradiance level of 6.5 kWh/m2/day at latitude tilt, our guarded, behind-the-fence, outdoor test facility provides traditional and custom engineering evaluations of solar components and systems.

Local, experienced engineering staff will assist on PV, CPV, or BIPV projects for grid-tie operation or individual loads, with multiple performance monitoring and reporting options.

Benefits at a Glance

- Get years of experience and expertise of solar engineering staff, located on-site

- Obtain a wide range of traditional and customer engineering test services, including Solar Thermal testing

- Gain access to multiple outdoor test facilities in varying climates in a global and regional network, including Tempe, Arizona, US; Bangalore, India; Gyeongsan, Korea; Cologne, Germany; Osaka and Yokohama, Japan; Shanghai, China; and Taichung, Taiwan – as well as additional North American facilities in multiple climate zones

- Avoid Cost, Weather and Space Availability issues for implementing test protocols at your site

- Take advantage of natural exposure to high heat, radiation, and dust

Our services include, but are not limited to:

- Performance and degradation monitoring

- Soiling and weathering studies

- Solar tracker accuracy measurements

- Performance ratio/energy yield assessments

- Validation of remote communication

- Interoperability of components

- Durability of components

Data collection and monitoring – options

All sensors and testing equipment are vetted for high accuracy with known uncertainty specifications. Redundant weather stations located on site include continuous monitoring of:

- Total global irradiance, horizontal

- Total global irradiance, in-plane

- Total UV radiation

- Ambient temperature

- Relative humidity and rainfall

- Wind speed and direction

Dedicated and/or custom sensors and testing equipment are also available.